The Mahr Group didn´t want to rely on past successes, but instead to use its strong position to rework its inventory management and product portfolio. Together with a team of consultants from Staufen AG, this manufacturer of measurement instruments in Göttingen was able to achieve its ambitious goals.

Mahr, a family-owned company currently managed by the fifth generation, recently achieved successes around the globe and further expanded its market position. Nevertheless, it was clear that there was still room for improvement and that some adjustments had to be made for this. “After some very successful years, we had gotten a bit lazy,” says Vice President Global Production Systems and internal project manager Dr. Thomas Ardelt about the company’s situation. “The primary goal of our cooperation with Staufen was therefore a comprehensive optimization of inventory management.” Mahr is known on the market for its broad product range and offering its customers a multitude of specific solutions, which have to remain available across long periods of time. That’s why the biggest challenge was to significantly reduce inventories without compromising the usual level of service for customers.

In April 2019 the Staufen team headed by project manager Christian Sprenger began its consulting activities with its first plant visit to Mahr in Göttingen. At the beginning of the project, first subprojects were defined and then worked through step by step as part of a tactical implementation plan. In the process, the consultants incorporated all areas of the company in order to exploit the greatest possible potential. In the “Sales and Operations Planning” process, for example, the product range and market knowledge were interlocked with quantity planning for production, which resulted in significantly improved delivery times and lower inventories. Thanks to clear structuring, short-cycle regular communication, consistent implementation, and the comprehensive coordination of the project management office, all expectations were fulfilled and in many cases, even exceeded.

The active, transparent cooperation between the Mahr project team and Staufen was the key to achieving a value stream orientation across the board.

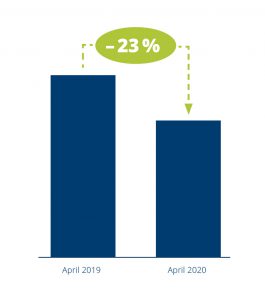

In addition to improving the striven-for KPIs,inventory volume was reduced by approximately 23% within a year.

Even the contact restrictions imposed by the COVID-19 pandemic could not compromise the project, which had reached the home stretch. To the contrary: the crisis proved that remote work doesn’t have to mean downtime. Thanks to clearly structured cooperation, it can be very effective. “When we had to switch to our video and cloud solutions due to the COVID-19 lockdown, the good partnership between Mahr and Staufen paid off again,” says Mahr Managing Director about the situation in spring 2020. “Despite the distance, we were able to meet – virtually – and formulate solutions together.”

The individual subprojects were oriented according to the following goals: optimization of inventory and warehousing, consolidation of the product range, simplification of articles and products, introduction of forecast planning, establishment of a toolbox system and strategy for using the same parts, improvement of communication between departments and locations, and elimination of discontinuities between systems. In order to illustrate how comprehensively the topic of inventory management was approached, the most important subprojects are depicted below:

CONSISTENT IMPLEMENTATION THANKS TO PROJECT MANAGEMENT OFFICE (PMO)

Through the PMO, coordinated and centralized control of all subprojects was made possible. This also helped with the finalization of the individual subproject profiles, the structure of the TIP and the common target picture that was developed with all managers. The PMO also included the establishment of a public infoboard, various SFM (Shop Floor Management) boards for subproject managers and regular status communication to the Mahr staff.

Regular and transparent communication across all levels and departmental boundaries was crucial for the sustainable success of the individual projects. Thanks to continuous monitoring, deviations from targets were detected early on so that any countermeasures that might be necessary could be initiated in good time. In addition, managers were called upon to show commitment and dedication – and did so. The PMO Board was completely integrated and is accessible via digital SharePoint, regardless of location.

VISION AND MISSION ARE RIGHT THANKS TO STRATEGY AND ORGANIZATION

The model and management principles were tuned up in the interest of comprehensive, long-term planning, goal-setting, and strategy implementation. Here, the focus was on the interlocking of market orientation with a value stream-oriented organization.

Under the program name Mahr 2025, the target image and direction for the next 5 years were formulated and specified. A critical component of the program is a BalanceScoreCard, which includes the most important topics, projects, and KPIs for all entrepreneurial dimensions. Alongside this, the most important cornerstones of a communication strategy were defined; the employees, managers, and customers were informed in detail and they were incorporated constantly.

OPTIMAL WAREHOUSING WITH SALES AND OPERATIONS PLANNING (S&OP)

A variety of processes, including sales, production, service, material, and financial planning were interlocked and harmonized. The required data is now collected according to uniform guidelines for global rolling forecast planning and cross-departmental sales and operations planning and consolidated in a uniform report. The measures for this have been coordinated company-wide.

Before the global roll-out, a lighthouse project was initiated in order to determine the basis for a global uniform S&OP implementation. The long-term S&OP success will be determined largely by planning quality and continuous regular communication. To guarantee this, a clear, digital S&OP cockpit was set up, which provides an optimal view of the relevant past data, plan values, and KPIs. The improved planning quality delivers a common understanding, transparency, and great acceptance across all hierarchical levels.

Via the S&OP process, the company has succeeded in optimally aligning inventories to the product range and quantities required. The flexible handling of capacities prevents the development of capacity driven inventory. At the same time, cooperation and coordination between the departments has improved. This can be traced to the new role of a defined S&OP team, represented by one person apiece from sales, product management, and production. The team acts as a moderator and interface between participating departments.

NO WASTE WITH OPERATIONAL EXCELLENCE (OPEX)

The core processes in the value-creation chain (assembly, production, and logistics) were optimized in the course of the Operational Excellence (OPEX) subproject. Overall, performance and transparency on the shop floor improved a great deal. As part of an internal value-stream analysis, a potential reduction of throughput time from 101 to 36 days was determined for a reference project. In addition to chaining assembly steps, a supermarket control circuit was also established for value-stream control.

In addition to reducing throughput time, attention was also paid to reducing waste in production and production-supporting processes as much as possible. The consistent nature of management assures an additional level of shop floor communication on the worker level as a new element of regular communication. This ensures that the changes can be made for the long term. The early incorporation of the employees allowed extensive enabling of value stream design, so that in future projects, additional measures could be planned and implemented internally by trained multipliers.

ALWAYS IN THE SERVICE OF THE CUSTOMER WITH LIFECYCLE MANAGEMENT

Mahr is known on the market for a very broad product range that includes many “classics” in addition to the latest market-leading products. The company has retained and supported many customers, some of them for decades – with retrofits, software updates, and spare parts. This requires extensive planning and great transparency about the product status of the entire portfolio. In order to achieve this, in a first step lifecycle statuses were defined and coordinated across functions. After that, a complete assignment of the lifecycle statuses defined in the project to the entire product range was undertaken with subsequent analysis and derivation of recommendations for action.

Via consistent run-up and follow-up control with structured communication along the entire location-spanning value-creation chain, a uniform overview and great transparency with regard to the lifecycle of existing products and those in development was created. By combining requirements from the market and customer point of view, it was possible to better orient things to customers’ needs. With consistent control of the product range using the LC status and in close coordination with service and sales, it has possible to reduce inventory thus far, and in the future, the hope is to do so even more.

WELL-POSITIONED FOR THE FUTURE

“Certainly the hardest thing at a company like Mahr, which is active around the world and set up in decentralized fashion, is to create a uniform understanding of the topic of inventory management,” comments Vice President Global Production Systems Dr. Ardelt when thinking back to the start of the project. Meanwhile, all the employees have seen the effects of their actions on inventories take concrete shape. “The old world has been replaced once and for all,” continues Dr. Ardelt. In sum, with this project the cornerstone was laid for a stronger market position. According to Managing Director Erath: “With Staufen, we created new processes and defined a product range so that we will be well-positioned for the future.”

That this re-measurement of the world will continue is something that Mahr’s Chief Operations Officer Erath doesn’t doubt: “The methodology that Staufen brought us has become Mahr’s methodology and in the future, it will still be applied across the company.” Thus, silo thinking in Göttingen is a thing of the past. “In addition to all technical questions and change to the processes, this will only work with an appropriate corporate culture. This is where the Staufen consultants, with their expert partnership, have inspired the Mahr organization more than I have ever experienced in the 37 years of my professional career.“

Please feel free to contact me if you want to get any further information about this topic

CHRISTIAN SPRENGER, Principal, STAUFEN.AG

Project management during the development and realization of restructuring concepts

Operational implementation of cost reduction and growth programs

Extensive experience in Controlling as well as in the creation of integrated financial plans

phone: +49 7024 8056 0, e-mail: contact@staufen.ag