Let’s take a little trip back in time.

We’ll begin in 2011. The term “Industry 4.0” is used for the first time at the Hannover Messe.

It becomes a bit more specific at the Hanover Messe 2013. The Industry 4.0 working group presents its final report with the title “Implementation Recommendations for the Future Project Industry 4.0.” It quickly becomes clear that this future is not a far-away vision, but that the digital-industrial revolution will pick up speed fast.

The next year, Staufen AG presents the German Industry 4.0 Index for the first time. German business proves it is self-confident. Although nearly three-quarters of the companies surveyed have not yet focused on the topic Industry 4.0 or they have restricted themselves to the role of an observer, they reclaim the global pole position for Germany on the path to the smart factory.

Now let’s jump to 2022. Despite the push that the pandemic gave to digitalization, according to the current Industry 4.0 Index, there is a dichotomy in German industry between digital pioneers and digital stragglers. Learn all the details in our study.

Michael Feldmeth

Project ManagerSTAUFEN.AG

As an experienced consultant and project manager in the fields of operational excellence and Lean Management, Dr. Michael Feldmeth holds a doctorate in engineering and is a trainer at Staufen Academy. He specializes in mechanical and plant engineering, automotive and vehicle construction, and medical technology. He has extensive expertise in plant development, factory design and in optimizing direct and indirect business processes.

Michael has experience of restructuring in the areas of production (manufacturing and assembly), logistics and order fulfillment, practical Shop Floor experience and a sound technical understanding of production processes.

About the Study

Staufen AG has compiled the German Industry 4.0 Index every year since 2014. Thus, the metric is nearly as old as the term Industry 4.0 itself. The 2022 index indicates that the German economy is threatening to split down the middle.

In 2022, the German Industry 4.0 Index was compiled as part of the study “Companies in change.” For this, we surveyed a total of 363 companies in Germany in the fall of 2021, a good two-thirds of whom are from the mechanical and plant engineering industry, the electrical industry, and the automotive sector.

The results

According to the Staufen study “Companies in Transformation,” which is conducted regularly, digitalization – current special effects aside – continues to be the greatest driver for changes in the German economy. That’s why the German Industry 4.0 Index 2022, for which Staufen AG surveyed more than 360 companies, is a very good indication of how the transformation is going in companies here at home.

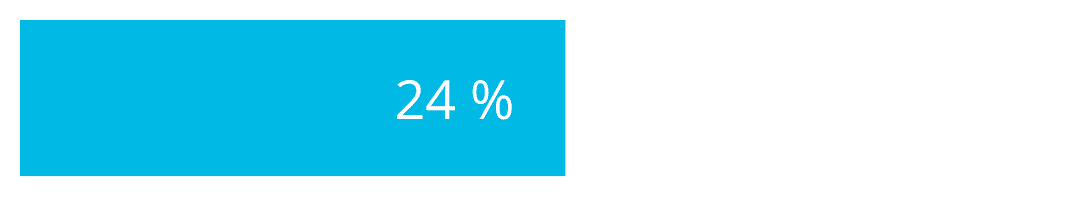

The current index paints a picture of a divided economy. While around one in two companies is already operationally implementing a smart factory – at least in individual projects – the others are still observing and testing or have not really engaged with the topic at all. Only 7% of companies have already implemented the “future project Industry 4.0” to a greater extent in their plant halls and development departments.

How far along is your company on the road to becoming a “Smart Factory”?

Shared economy: A good one in two companies is already operationally implementing the smart factory.

Gap between digital pioneers and digital stragglers

The consequences of this digital dichotomy are not great for Germany as a business location: For the first time since it was compiled, the German Industry 4.0 Index has stagnated at 45 points. For context: In 2014, the index started with a value of 16 points.

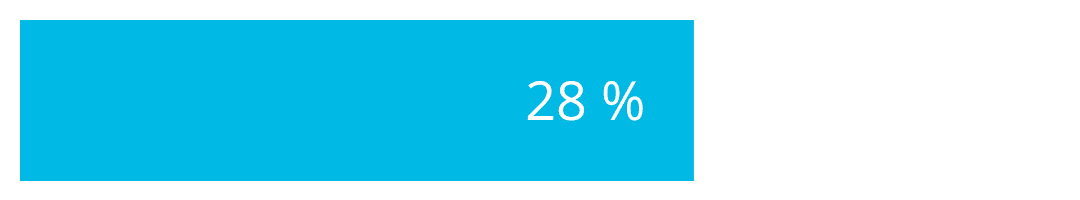

If we also consider how far advanced companies are in developing digital products and services, this division into digital pioneers and digital stragglers is likely to become even more pronounced in the future – after all, more than a third of smart factory companies now also offer products and/or services with 4.0 features or already offer completely new business models based on 4.0.

Since this development has been ongoing for a few years, the digital experts at Staufen AG started compiling a Smart Business Index in addition to the original Smart Factory Index. Initially, some of the digital pioneers – regardless of which industry they are in – had to pay apprenticeship dues and recall some of their new developments or rework them completely, in the meantime, the digital pioneering spirit is becoming more profitable.

In addition to increasing their own efficiency through Industry 4.0, more and more companies are also digitizing their products and services or even developing entire 4.0 business models. What is the situation like in your company?

Digital pioneers: The path from the Smart Factory leads to smart products and services.

The main challenge is to question which things are no longer valid and can therefore be dispensed with. Due to limited resources, change in companies is taking place much more slowly than technical solutions are developing.

Thomas Urbanczyk, Vice President Production, TADANO FAUN GmbH

Digitalization as a chain reaction

The German Industry 4.0 Index 2022 has a very clear message: From the smart factory, the path leads toward smart products and services. And powerfully so: The Industry 4.0 Index (Smart Business), which has been collected since 2018, has increased significantly over the past three years. Adaptability therefore knows no end, but rather triggers a positive chain reaction.

Michael Feldmeth

Project ManagerSTAUFEN.AG

As an experienced consultant and project manager in the fields of operational excellence and Lean Management, Dr. Michael Feldmeth holds a doctorate in engineering and is a trainer at Staufen Academy. He specializes in mechanical and plant engineering, automotive and vehicle construction, and medical technology. He has extensive expertise in plant development, factory design and in optimizing direct and indirect business processes.

Michael has experience of restructuring in the areas of production (manufacturing and assembly), logistics and order fulfillment, practical Shop Floor experience and a sound technical understanding of production processes.

You have questions? Get in touch with us.

I would be very pleased if the ideas and examples named here would mean that your company would become part of the team in order to write the next chapter in the exciting Industry 4.0 journey.

More about this topic

Digitalization & Industry 4.0

Intelligent Industry 4.0 production processes can be applied to accomplish a variety of objectives. These include achieving greater productivity and efficiency, fulfilling consumer specifications faster and more expediently, and developing brand-new industrial products and business models. Small and mid-sized companies often have a particular need for this kind of consulting and guidance.

Read more

Process Optimization and Customer Focus: The Path of the Digital Pioneer

Digital pioneers distinguish themselves from other companies in that a chain reaction has triggered their internal digitalization. They did not stop with process optimization and efficiency increases; instead, digitalization has illuminated other areas as well, such as customer focus. As a result, the pioneers orient their processes and products so that they provide their customers with additional added value. Dr. Lars Reinkemeyer, Vice President of Customer Transformation at Celonis, and Frank Krüger, Senior Partner at Staufen AG are responsible for the topic of digitalization. They explain the path of digital pioneers and reveal how other companies can also go down this path.

Read more